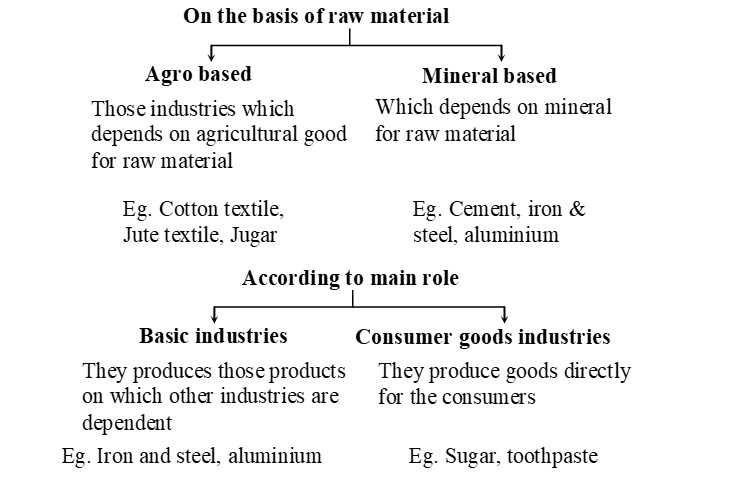

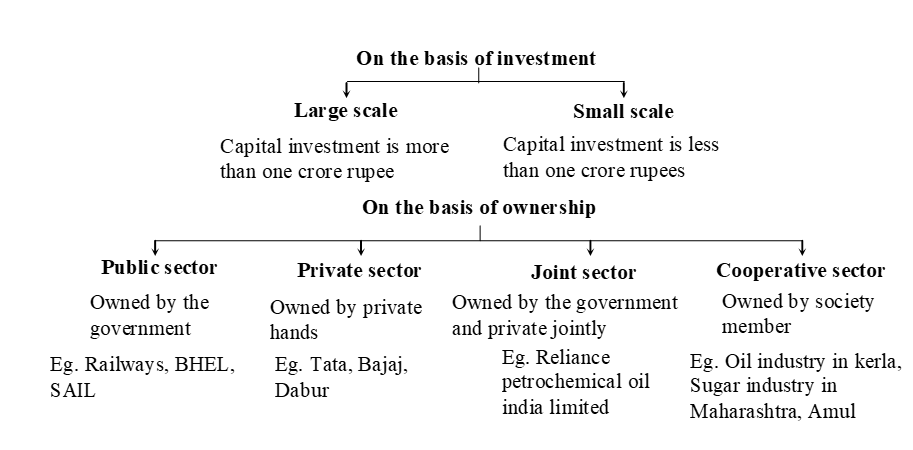

Understanding the types of industries is an important part of Class 8 Geography and Economics. Industries are classified based on ownership, size, raw materials, and production type. The following section explains key terms like agro-based industries, basic industries, consumer industries, and manufacturing industries, along with examples for better learning.

- Agro based industries: Industries that process agricultural raw material, e.g. Cotton textile.

- Basic industry: Industry on which several large-scale and small-scale industries depend, e.g., Iron and steel, chemical.

- Consumer industries: Industries which produce goods like plastics, utensils for the consumption of people.

- Cooperative industries: Industries owned and organized by members form a cooperative society and pool their resources for profits and losses.

- Heavy industry: These industries use heavy raw materials to produce heavy goods like heavy engineering.

- Joint sector industries: Industries which are jointly owned by both the state and some private industrialists or firms.

- Large scale industries: Industries using extensive raw materials, capital, labour and power to produce goods on large scale.

- Light industry: Industries using light raw materials to produce light goods like paper, cotton textiles.

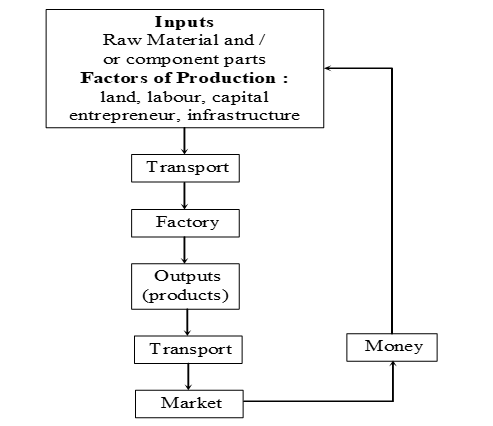

- Manufacturing: An economic activity where raw materials are converted into finished goods with the help of machines.

- Public sector industries: An industry in which a state government or its agencies undertakes economic activities and controls means of production and distribution.

- Private sector industries: Industries owned and run by private individuals like Tata Iron & Steel Company, Reliance Industries.

- Small scale industries: The industries employing small number of employees and a capital investment of less than rupees one crore, e.g., readymade garments.

Manufacturing

Production of goods in large quantities after processing from raw materials to more valuable products is called manufacturing.

Importance of Manufacturing:

Manufacturing industries not only help in modernising agriculture, which forms the backbone of our economy, they also reduce the heavy dependence of people on agricultural income by providing them jobs in secondary and tertiary sectors.

- Industrial development is a precondition for eradication of unemployment and poverty from our country.

- Export of manufactured goods expands trade and commerce, and brings in much needed foreign exchange.

- Countries that transform their raw materials into a wide variety of furnished goods of higher value are prosperous.

Agriculture and Industry:

- Agriculture and industry go hand in hand and are supplementary to each other in many ways.

- Industry provides new tools, and implements as well as other inputs of agriculture to boost agricultural productivity.

- The agro based industries depend on agriculture for raw materials and industries sell their products such as irrigation pumps, fertilizers, insecticides, pesticides, plastic and PVC pipes, machines and tools, etc. to the farmers.

- Thus, development and competitiveness of manufacturing industry has not only assisted agriculturists in increasing their production but also made the production processes very efficient.

Contribution Of Industries to National Economy:

Over the last two decades. The share of manufacturing sector has stagnated at 17 percent of GDP-out of a total of 27 percent for the industry which includes 10 percent for mining, quarrying, electricity and gas.

The trend of growth rate in manufacturing over the last decade has been around 7 percent per annum. The desired growth rate over the next decade is 12 percent. Since 2003, manufacturing is once again growing at the rate of 9 to 10 percent per annum. The National Manufacturing Competitiveness Council (NMCC) has been set up with this objective.

Industrial Location

Industrial locations are complex in nature. These are influenced by availability of raw material, labour, capital, power and market, etc. It is rarely possible to find all these factors available at one place. Consequently, manufacturing activity tends to locate at the most appropriate place where all the factors of industrial location are either available or can be arranged at lower cost. After an industrial activity starts, urbanisation follows. Sometimes, industries are located in or near the cities.

Industry Market Linkage:

Thus, industrialisation and urbanisation go hand in hand. Cities provide markets and also provide services such as banking, insurance, transport, labour, consultants and financial advice, etc. to the industry. Many industries tend to come together to make use of the advantages offered by the urban centres known as agglomeration economies. Gradually, a large industrial agglomeration takes place.

Classification of Industries:

Agro Based Industries

Agro-based industries play a vital role in the development of India's rural economy, which has been receiving increasing attention from the central as well as state government, in view of its importance to the national reconstruction.

The economic prosperity of a developing country like India depends largely on the development of agro-based industries which in turn leads to the creation of forward and backward linkages of the development process on large scale by making mutual complementary of agriculture and industries.

The study of essentially empirical in nature and attempts to make an economic-analysis of agro based industries in India and Karnataka in general and Hyderabad Karnataka region in particular for the post liberalization period, i.e., from 1990-91 to 2004-05.

Industries which get their raw material from agricultural sector such as sugar, edible oil, silk, jute, woolen textiles, cotton textile.

Textile Industries

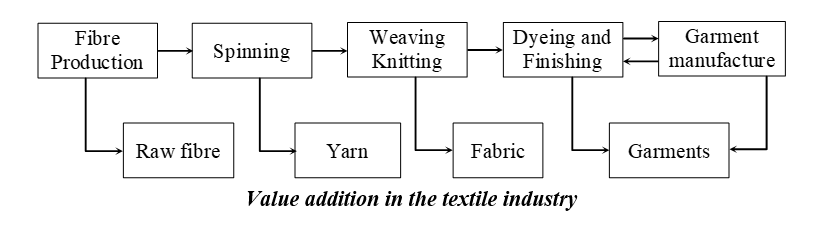

The textile industry occupies unique position in the Indian economy, because it contributes significantly to industrial production (14 per cent), employment generation (35 million persons directly – the second largest after agriculture) and foreign exchange earnings (about 24.6 per cent). It contributes 4 per cent towards GDP. It is the only industry in the country, which is self-reliant and complete in the value chain i.e., from raw material to the highest value added products.

History Of Cotton Textiles In India:

In ancient India, cotton textiles were produced with hand spinning and handloom weaving techniques. After the 18th century, power-looms came into use. Our traditional industries suffered a setback during the colonial period because they could not compete with the mill-made cloth from England.

Today, there are nearly 1600 cotton and human made fibre textile mills in the country. About 80 per cent of these are in the private sector and the rest in the public and cooperative sectors. Apart from these, there are several thousand small factories with four to ten looms. In the early years, the cotton textile industry was concentrated in the cotton growing belt of Maharashtra and Gujarat.

Reasons For Concentration In Gujarat And Maharastra:

The cotton textile is a highly localised industry right from the beginning mainly in the cotton growing belt of Maharashtra and Gujarat. Localisation factors were :

(i) Availability of raw cotton in Gujrat and Maharashtra.

(ii) Traditional labour is available in these states.

(iii) Moist climate in these states also helps in spinning.

(iv) Infrastructure facilities are developed in these states.

(v) Port facilities are located near these states.

Features Of Cotton Textile Industry:

- It is an agro-based industry thus a large numbers of farmers get their living from it.

- There are a line of activities from cotton Ball pluckers to workers engaged in weaving, spinning, dyeing, designing, packaging, tailoring and sewing.

- Many other ancillary industries have come up around cotton mills such as chemicals and dyes engineering works, packaging materials and mill store hence it is a labour intensive industry.

- Cotton textile industry is an example of centralized and decentralized industry.

- Features like spinning is cetralised in Maharashtra, Gujarat and Tamil Nadu but weaving is highly decentralized for incorporating Traditional skill and designs of weaving in silk, cotton Zari, embroidery etc.

- India has world class production in spinning, but weaving supplies low quality of fabric as it cannot use much of the high quality yarn produced in the country.

- Weaving is done by handloom, power loom and in mills.

- The handspun khadi provides large scale employment to weavers in their homes as cottage industry.

- India has bright future in cotton textile industry and wide scope in exports.

- Exporting countries include Japan, U.S.A., Russia, France, Singapore, East European countries, African countries, Nepal and Srilanka.

- At around 34 million, India stands second largest installed capacity of spindles in the world after China.

- One fourth of the total trade of cotton yarn comes from India in the world trade.

- However, our trade in garments is only 4 per cent of the world’s total. Our spinning mills are competitive at the global level and capable of using all the fibres we produce.

- THE PROBLEMS OF WEAVING SECTOR:

- The weaving, knitting and processing units cannot use much of the high quality yarn that is produced in the country.

- There are some large and modern factories in these segments, but most of the production is fragmented in small units, which cater to the local market.

- This mismatch between the large and small unit is a major drawback for the industry.

- As a result, many of our spinners export cotton yarn while apparel garment manufactures have to import fabric.

Problems Of Cotton Textile Industry:

- (i) Most of the production is in fragmented small units, which cater to the local market.

- (ii) The weaving knitting and processing units cannot use much of the high quality yarn that is produced in the country.

- (iii) Scarcity of good quality cotton, outdated machinery, erratic power supply, low productivity of labour and stiff competition with synthetic fiber industry are some other major problems faced by the industry.

Trade: India exports yarn to Japan. Our trade in garments is only 4% of the world's total. Readymade garments are exported to U.S.A., U.K, Russia, France, European countries, Nepal, Singapore, Sri-Lanka and African countries.

Jute Textiles

India is the largest producer of raw jute and jute goods and stands at second place as an exporter after Bangladesh. There are about 70 jute mills in India. Most of these are located in West Bengal, mainly along the banks of the The first jute mill was set up near Kolkata in 1859 at Rishra. After Partition in 1947, the jute mills remained in India but three-fourth of the jute producing area went to Bangladesh.

Factors Responsible for Localization of Jute industry is Hugli Basin proximity of the jute producing areas inexpensive water transport supported by a good network of railways roadways and waterways to facilitate movement of raw material to the mills abundant water for processing raw jute Cheap labour from West Bengal and adjoining states of Bihar, Orissa and Uttar Pradesh.

Kolkata as a large urban centre provides banking, insurance and port facilities for export of jute goods.

Problems of Jute Industry:

(i) Less demand for jute carpets and packing materials.

(ii) High production costs.

(iii) Stiff competition in international market.

(iv) Competition from synthetic substitutes.

However, the internal demand has been increased due to the Government policy of mandatory use of jute packaging. In 2005, National Jute policy was formulated with the objective of increasing productivity, improving quality, ensuring good prices to the Jute farmers and enhancing the yield per hectare.

Steps Taken To Protect Jute Industry:

- To stimulate demand, the products need to be diversified.

- In 2005, National Jute Policy was formulated with the objective of increasing productivity, improving quality, ensuring good prices to the jute farmers and enhancing the yield per hectare.

- The main markets are U.S.A., Canada, Russia, United Arab Republic, U.K. and Australia.

- The growing global concern for environment friendly, biodegradable materials had once again opened the opportunity for jute products.

Trade: Exported to U.S.A, Canada, Russia, United Arab Republic, Australia and U.K.

Importance: India stands second as a world producer of sugar but occupies the first place in the production of gur and khandsari. The raw material used in this industry is bulky, and in haulage its sucrose content reduces.

Distribution:

There are over 460 sugar mills in the country spread over Uttar Pradesh, Bihar, Maharashtra, Karnataka, Tamil Nadu, Andhra Pradesh and Gujarat along with Punjab, Haryana and Madhya Pradesh. Sixty per cent mills are in Uttar Pradesh and Bihar. This industry is seasonal in nature so, it is ideally suited to the cooperative sector.

Migration of sugar industry to south India:

In recent years, there is a tendency for the mills to shift and concentrate in the southern and western states, especially in Maharashtra, This is because the cane produced here has a higher sucrose content. The cooler climate also ensures a longer crushing season. Moreover, the cooperatives are more successful in these states.

Problems of sugar Industry:

Major challenges include the seasonal nature of the industry. Due to which it becomes less profitable.

Old and inefficient methods of production.

Transport delay in reaching cane to factories.

Baggase are not used properly. So there is wastage.

Mineral Based Industries

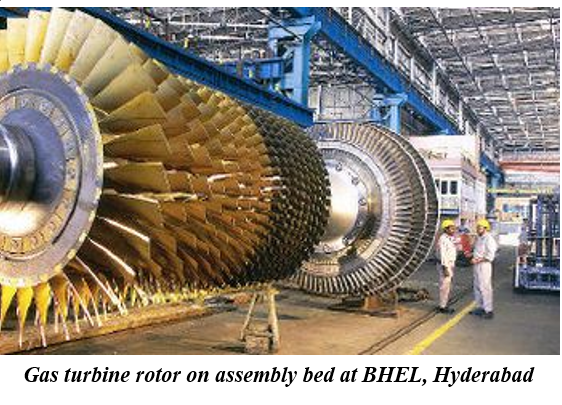

Iron And Steel Industry:

History and present status:

(i) First industry was established at Portonova in Tamil Nadu, followed by Kulti in West Bengal.

(ii) First integrated steel plant came up at Jamshedpur in 1907.

(iii) Presently there are 10 primary integrated Iron and Steel plant and around 200 mini steel plants.

Importance:

The iron and steel Industry is the basic industry since all the other industries — heavy, medium and light, depend on it for their machinery. Steel is needed to manufacture a variety of engineering goods, construction material, defence, medical, telephonic, scientific equipment and a variety of consumer goods.

Production and consumption of steel is often regarded as the index of a country’s development. Iron and steel is a heavy industry because all the raw materials as well as finished goods are heavy and bulky entailing heavy transportation costs. Iron ore, coking coal and lime stone are required in the ratio of approximately 4 : 2 : 1. Some quantities of manganese, are also required to harden the steel.

Today with 32.8 million tons of steel production, India ranks ninth among the world crude steel producers. It is the largest producer of sponge iron. Inspite of large quantity of production of steel, per capita consumption per annum is only 32 kg.

In the 1950s China and India produced almost the same quantity of steel. Today, China is the largest producer. China is also the world’s largest consumer of steel. In 2004, India was the largest exporter of steel which accounted for 2.25 per cent of the global steel trade.

Reason for concentration of Iron and Steel Industry in Chotanagpur plateau:

This industry in concentrated into Chotanagpur plateau because of the relative advantages this region has for the development of this industry.

Chotanagpur plateau has rich reserves of Iron ore, coal and lime stone and they are found very close to each other. This reduces transportation cost.

Damodar River and its tributaries provide water needed by this industry.

This region has developed thermal and hydro power plants which provide electricity.

Cheap and skilled labour is available.

This region has developed network of railways and roadway.

Kolkata and Haldia ports are very close to this region which facilitates export.

Problems of Iron and steel industry:

(a) High costs and limited availability of coking coal

(b) Lower productivity of labour

(c) Irregular supply of energy and

(d) Poor infrastructure.

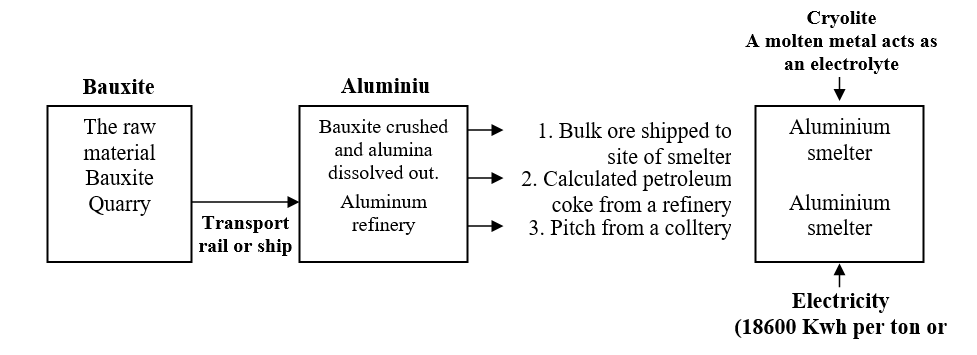

Aluminium:

In 2004, India produced over 600 million tons of aluminium. Bauxite, the raw material used in the smelters is a very bulky, dark reddish coloured rock. The flow chart given below shows the process of manufacturing aluminium. Regular supply of electricity and an assured source of raw material at minimum cost are the two prime factors for location of the industry.

Aluminium Smelting:

Aluminium smelting is the second most important metallurgical industry in India. It is light, resistant to corrosion, a good conductor of heat, mallable and becomes strong when it is mixed with other metals. It is used to manufacture aircraft, utensils and wires. It has gained popularity as a substitute of steel, copper, zinc and lead in a number of industries. There are 8 aluminium smelting plants in the country located in Orissa (Nalco and Balco), West Bengal, Kerala, Uttar Pradesh, Chattisgarh.

Ratio between Ores and Aluminium

4 to 6 tons of bauxite ®2 tons of alumina ® 1 ton of alumnium

Process of manufacturing in Aluminium industry:

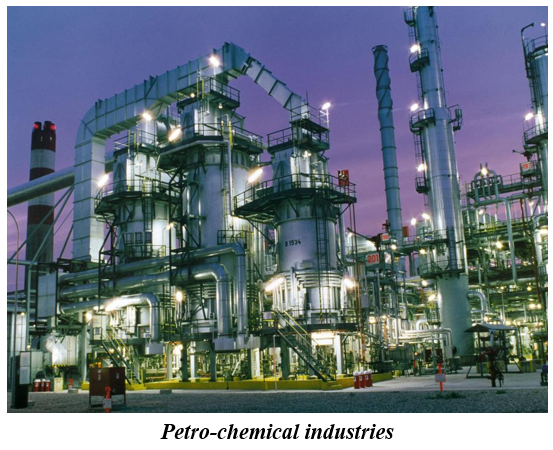

Chemical Industry:

The Chemical industry in India is fast growing and diversifying. It contributes approximately 3 per cent of the GDP. It is the third largest in Asia and occupies the twelfth place in the world in term of its size. It comprises both large and small scale manufacturing units. Rapid growth has been recorded in both inorganic and organic sectors. Inorganic chemicals include sulphuric acid (used to manufacture fertilisers, synthetic fibres, plastics, adhesives, paints, dyes stuffs), nitric acid, alkalies, soda ash (used to make glass, soaps and detergents, paper) and caustic soda. These industries are widely spread over the country.

Organic chemicals include petrochemicals, which are used for manufacturing of synthetic fibers, synthetic rubber, plastics, dye-stuffs, drugs and pharmaceuticals. Organic chemical plants are located near oil refineries or petrochemical plants. The chemical industry is its own largest consumer. Basic chemicals undergo processing to further produce other chemicals that are used for industrial application, agriculture or directly for consumer markets.

Fertilizer Industry:

(i) First fertilizer industry plant was established at Ranipet in Tamil Nadu in 1906, real growth became with the establishment of plan". at Sindri by the Fertilizer Corporation of India.

(ii) India is the third largest producer of nitrogenous fertiliser. There are 57 fertilizer units manufacturing nitrogenous and complex nitrogenous fertiliser, 29 for urea and 9 for producing ammonium sulphate as a by-product and 68 other small units produce single super phosphate.

Factors that have helped in the widespread location of fertilizer industry in India:

After the Green Revolution the industry expanded to several other parts of the country. Gujarat, Tamil Nadu, Uttar Pradesh, Punjab and Kerala contribute towards half the fertilizer production. Other significant producers are Andhra Pradesh, Orissa, Rajasthan, Bihar, Maharashtra, Assam, West Bengal, Goa, Delhi, Madhya Pradesh and Karnataka.

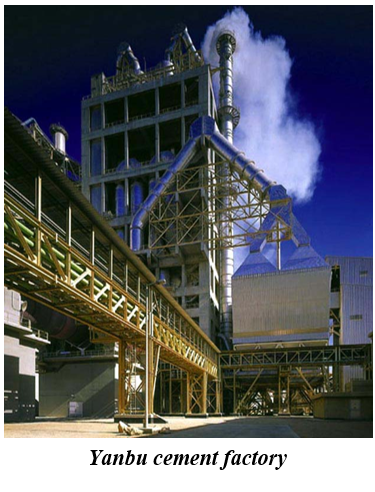

Cement Industry:

- Cement is raw material as well as a resource in cementing other industry. So it is called infrastructure core industry. Commercial activities in recent time have boosted this industry a lot.

- Construction of roads, dams, airports, bridges, factories, housing colonies, Multistory buildings and now the Malls has completely transformed this industry.

- This industry requires bulky and heavy raw materials like limestone, silica, alumina and gypsum.

- Coal and electric power are needed apart form rail transportation.

- So these industries should be located near the source of raw material.

- The industry has strategically located in Gujarat that has suitable access to the market in the Gulf countries.

- The first cement plant was set up in Chennai in 1904. After Independence the industry expanded.

- Decontrol of price and distribution since 1989 and other policy reforms led the cement industry to make rapid strides in capacity, process, technology and production.

Automobile Industry:

Automobiles provide vehicle for quick transport of good services and passengers. Trucks, buses, cars, motor cycles, scooters, three-wheelers and multi-utility vehicles are manufactured in India at various centres. After the liberalisation, the coming in of new and contemporary models stimulated the demand for vehicles in the market, which led to the healthy growth of the industry including passenger cars, two and threewheelers. This industry had experienced a quantum jump in less than 15 years. Foreign Direct Investment brought in new technology and aligned the industry with global developments. At present, there are 15 manufacturers of passenger cars and multiutility vehicles, 9 of commercial vehicles, 14 of the two and three-wheelers. The industry is located around Delhi, Gurgaon, Mumbai, Pune, Chennai, Kolkata, Lucknow, Indore, Hyderabad, Jamshedpur and Bangalore.

Information Technology And Electronics Industry:

The electronics industry covers a wide range of products from transistor sets to television, telephones, cellular telecom, pagers telephone exchange, radars, computers and many other equipments required by the telecommunication industry.

- Bangalore has emerged as the electronic capital of India. Other important centres for electronic goods are Mumbai, Delhi, Hyderabad, Pune, Chennai, Kolkata, Lucknow and Coimbatore.

- 18 software technology parks provide single window service and high data communication facility to software experts.

- A major impact of this industry has been on employment generation. Upto 31 March 2005, the IT industry employed over one million persons.

- This number is expected to increase eight-fold in the next 3 to 4 years. It is encouraging to know that 30 per cent of the people employed in this sector are women.

- This industry has been a major foreign exchange earner in the last two or three years because of its fast growing Business Processes Outsourcing (BPO) sector.

- The continuing growth in the hardware and software is the key to the success of IT industry in India.

Industrial Pollution And Environmental Degradation

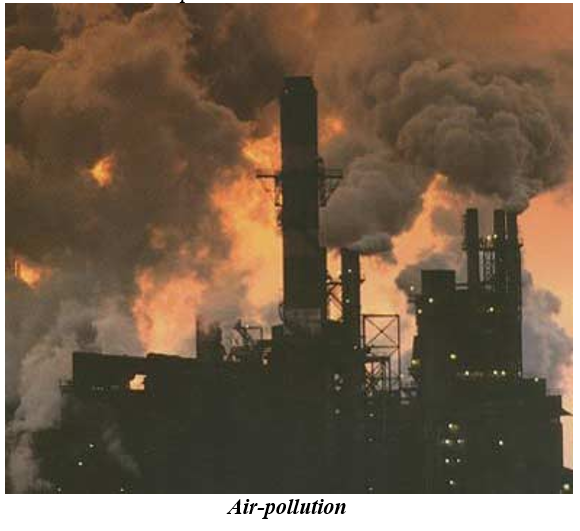

Air Pollution:

Cause: Smoke emitted by the industries carries a higher porportion of undesirable gases, materials, consisting of both solid and liquid particles which affect human health, animals, plants, materials and the atmosphere.

Remedy: Air pollution can be controlled by:

(i) Better fuel selection and utilization, use of oil instead of coal in the industries.

(ii) Use of equipments like inertial separators, filters, precipitators and scrubbers.

Water Pollution:

Causes:

(i) Industrial affluent are discharged into rivers which are both organic and inorganic.

(ii) Paper pulp, textiles, chemical, petroleum refining, tannery and electroplating are the major industries creating water pollution.

Remedy: Treatment of industrial liquids can be done in three phases

(i) Primary treatment by mechanical process.

(ii) Secondary treatment by biological process,

(iii) Tertiary treatment by biological, chemical and physical process which includes recycling of waste water.

Noise Pollution:

Noise pollution not only results in irritation and anger, it can also cause hearing impairment, increased heart rate and blood pressure among other physiological effects. Unwanted sound is an irritant and a source of stress. Industrial and construction activities, machinery, factory equipment, generators, saws and pneumatic and electric drills also make a lot of noise.

Few measures to control land and soil pollution.

(i) Collection of wastes from different places.

(ii) Dumping and disposing the waste by land filling.

(iii) Recycling of the wastes for further use.

Thermal Pollution:

- Thermal pollution of water occurs when hot water from factories and thermal plants is drained into rivers and ponds before cooling.

- Wastes from nuclear power plants, nuclear and weapon production facilities cause cancers, birth defects and miscarriages.

- Soil and water pollution are closely related. Dumping of wastes specially glass,, harmful chemicals, industrial effluents, packaging, salts and garbage renders the soil useless.

- Rain water percolates to the soil carrying the pollutants to the ground and the ground water also gets contaminated.

Control Of Environmental Degradation:

Every litre of waste water discharged by our industry pollutes eight times the quantity of freshwater. How can the industrial pollution of fresh water be reduced? Some suggestions are-

(i) Minimising use water for processing by reusing and recycling it in two or more successive stages

(ii) Harvesting of rainwater to meet water requirements

(iii) Treating hot water and effluents before releasing them in rivers and ponds.

Treatment of industrial effluents can be done in three phases

(a) Primary treatment by mechanical means. This involves screening, grinding, flocculation and sedimentation.

(b) Secondary treatment by biological process

(c) Tertiary treatment by biological, chemical and physical processes. This involves recycling of wastewater.

Overdrawing of ground water reserves by industry where there is a threat to ground water resources also needs to be regulated legally. Particulate matter in the air can be reduced by fitting smoke stacks to factories with electrostatic precipitators, fabric filters, scrubbers and inertial separators. Smoke can be reduced by using oil or gas instead of coal in factories. Machinery and equipment can be used and generators should be fitted with silencers. Almost all machinery can be redesigned to increase energy efficiency and reduce noise. Noise absorbing material may be used apart from personal use of earplugs and earphones.

Example Of NTPC:

NTPC is a major power providing corporation in India. It has ISO certification for EMS (Environment Management System) 14001. The corporation has a pro-active approach for preserving the natural environment and resources like water, oil and gas and fuels in places where it is setting up power plants.

This has been possible through-

(a) Optimum utilisation of equipment adopting latest techniques and upgrading existing equipment.

(b) Minimising waste generation by maximising ash utilisation.

(c) Providing green belts for nurturing ecological balance and addressing the question of special purpose vehicles for afforestation.

(d) Reducing environmental pollution through ash pond management, ash water recycling system and liquid waste management.

(e) Ecological monitoring, reviews and online database management for all its power stations.

Summary

1. Importance of Manufacturing :

Manufacturing sector is considered the backbone of development in general and economic development.

(i) Manufacturing industries helps in modernising agriculture.

(ii) It reduce the heavy dependence of people on agriculture income by providing them jobs.

(iii) Helps in eradication of unemployment & poverty.

(iv) Helps in bringing down regional disparities.

(v) Exports of manufactured goods expand trade & commerce.

2. Iron and Steel Industry :

(i) Iron and steel industry is the basic industry steel is needed to manufacture a variety of engineering goods, construction material, defence, medical, telephonic, scientific equipment and variety of consumer goods.

(ii) Iron and steel industry is a heavy industry because all raw material as well as finished goods are heavy and bulky entailing heavy transportation costs. Iron ore, coking coal and lime stone are required in 4 : 2 : 1

(iii) India is an important iron and steel producing country in the world yet we lag behind because.

(a) High costs and limited availability of coking coal.

(b) Lower productivity of labour.

(c) Irregular supply of energy.

(d) Poor infrastructure.

3. Industrial Pollution and Environmental Degradation :

Industries contribute significantly to India’s economic growth and development but increase in pollution results in degradation of environment.

FOUR TYPES OF POLLUTION:

(a) Air: caused by undesirable gases such as sulpher dioxide and carbon monoxide, air borne particles such as dust, sprays, mist & smoke.

(b) Water Pollution: Caused by organic & inorganic industrial wastes such as release of lead, mercury pesticides, fertilizers, synthetic chemical, plastics, rubber, fly ash, phosphogypsum etc.

(c) Thermal Pollution: Caused by nuclear power plants nuclear & weapon production cause cancers birth defects & miscarriages.

(d) Noise Pollution: Cause hearing impairment, increased heart rate & blood pressure by making unwanted noise.

(IV) Control of Environment Degradation:

(i) Minimising the use of water by reusing recycling.

(ii) Harvesting rainwater to meet water requirement.

(iii) Treatment of hot water and effluents before releasing in ponds & rivers, involves 3 steps.

- Primary treatment by mechanical means.

- Secondary treatment by biological process.

- Tertiary treatment by biological chemical & physical processes.

SOLVED QUESTIONS

- What is manufacturing? To which sector of economy does it belong?

Ans.Manufacturing: Production of goods in large quantities after processing from raw materials to more valuable products is called manufacturing. Manufacturing belongs to secondary sector.

- What are ‘agglomeration economies’ in the industrial context?

Ans. Many industries tend to come together to make use of the advantage offered by the urban centres known as agglomeration economies. Gradually a large industrial agglomeration or clustering takes place.

- Distinguish between a small-scale and large-scale industry.

Ans. Small scale industry – Industry in which capital investment on the assets of a unit is not more than one crore rupees.

Large scale industry has a capital investment of more then one crore.

- Distinguish between agro-based and mineral-based industry.

Ans. (i) Agro-based industry obtain their raw material from agricultural sector e.g. cotton textile and sugar industry, etc.

(ii) Mineral-based get their raw material from the mining sector e.g. Iron and steel industry.

- Name four major cotton yarn and cotton goods importing countries

Ans. The major importing countries are : Japan, U.S.A., U. K., Russia and France.

- Name four countries which are the main buyers of Indian jute products.

Ans. The main buyers of Indian jute products are:

- U.S.A. 2. Canada 3. Russia 4. U.K.

- Name the fertilizers which India needs to import and why?

Ans. Potash is entirely imported as India does not have any reserves of commercially usable potash or potassium compounds in any form.

- List four raw materials used in cement industry.

Ans. Four raw materials used in cement industry are :

(i) limestone (ii) silica (iii) alumina (iv) gypsum.

- Write the distribution of electronics industry.

Ans. Bangalore has emerged as the electronic capital of India. Other important centres of electronic goods are the four mega cities of Hyderabad, Pure, Hyderabad and Coimbatore.

- Write the contribution and present growth rate of manufacturing sector in national economy. Suggest two measures to increase the industrial growth rate.

Ans. The share of manufacturing sector had stagnated at 17% of GDP. The trend of growth rate over the last decade has been around 7% per annum. Since 2003, it has shown the increased growth rate of 9-10% per annum. The desired growth rate over the next decade is 12%. To attain this target, following two steps can be taken.

(i) The National Manufacturing Competitiveness Council (NMCC) has been established.

(ii) Renewed effort by the industry to improve productivity.

- “Industrialization and urbanization go hand in hand”. Explain.

Ans. (i) After an industrial activity starts, urbanization follows. As industry requires various other services some industries located in and around the cities.

(ii) Thus industrialization and urbanization go hand in hand. Cities provide markets, service, such as banking, insurance, transport, labour agglomeration or clustering takes place.

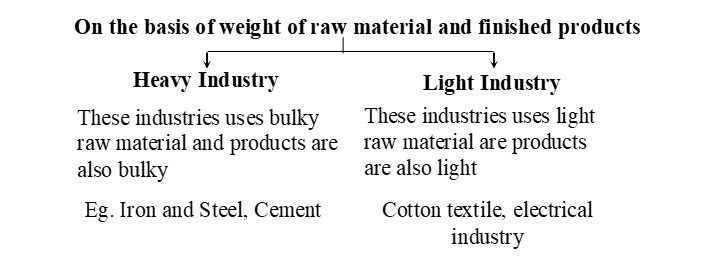

- State any five basis on which industries are classified.

Ans. (i) On the basis of raw materials used – Agro-based and mineral-based

(ii) According to their main role - Basic and consumer industries.

(iii) On the basis of capital investment – small-scale and large-scale industries.

(iv) On the basis of ownership – public sector, private sector, cooperative sector, joint sector.

(v) Based on the bulk and weight of raw material and finished goods – Heavy industries, light industries.

- Explain four types of industries on the basis of ownership and give one example of each.

Ans. Four types of industries based on ownership are :

(i) Public Sector industries: They are owned and operated by Government agencies, e.g. BHEL, SAIL, etc.

(ii) Private Sector industries are owned and operated by an individual or a group of individuals, e.g. TISCO, Bajaj Auto Ltd., Dabur Industries.

(iii) Joint Sector industries are jointly run by Public (government) and Private Sector (individuals), e.g. Oil India Ltd.

(iv) Cooperative Sector industries are owned and operated by the producers or suppliers of raw materials, workers, or both. They pool in the resources and share the profits or losses proportionately, e.g. sugar industry in Maharashtra and coir industry in Kerala.

- List four factors which favoured the location and concentration of cotton textile industry in Maharashtra and Gujrat in early years.

Ans. Four factors which favoured the concentration of textile industry.

(i) Availability of raw cotton as these states are the leading producer of cotton.

(ii) Transportation and accessible port facilities are developed in these states.

(iii) Moist climate favours spinning of threads.

(iv) Abundant labour is available.

- Write four major problems/challenges faced by the jute industry.

Ans. Four major challenges faced by the jute industry :

(i) Stiff competition in the international market from synthetic substitutes.

(ii) Stiff competition from other competitors like Bangladesh, Brazil, Philipines, Egypt and Thailand.

(iii) The demand for jute products is declining both in international as well as domestic markets.

(iv) The cost of production is high and many jute mills still have obsolete machinery,

(v) Demand of jute carpet and packing material is decreasing.

- Write three factors which led to the rapid expansion of cement industry.

Ans. Three factors that led to rapid expansion of Cement Industry are:

(i) Decontrol of cement price since 1989.

(ii) Decontrol of distribution of cement since 1989.

(iii) Many other policy reforms led the cement industry to take strides in capacity, process, technology and production. Today, there are 128 large plants and 332 mini cement plants in the country, producing variety of cement.

(iv) Demand of cement has increased especially after the globalization.

- "The textile industry occupies a unique position in the Indian Economy." Give five supportive arguments in favour of this statement.

Ans. It occupies a unique position in the Indian Economy because :

(i) It contributes significantly to industrial production (14%).

(ii) It employs largest number of people after agriculture, i.e. 35 million persons, directly.

(iii) Its share in the foreign exchange earnings is about 24.6%.

(iv) It contributes 4% towards GDP.

(v) It is the only industry in the country which is self-reliant and complete in the value chain, i.e. from raw material to the highest value added products.

- Write six factors which are responsible for the concentration of jute mills in Hoogly basin.

Ans. Six factors responsible for the concentration of Jute Industry.

(i) Proximity of the jute producing areas as west Bengal is the leading producer.

(ii) Inexpensive water transport provided by the Hoogly basin.

(iii) It is well connected by a good network of railways, waterways and roadways to facilitate movement of raw materials to the mills.

(iv) Abundant water for processing raw jute is available in hoogly basin.

(v) Availability of cheap labour from West Bengal and the adjoining States of Bihar, Orissa and U.P.

(vi) Kolkata as a port and large urban centre provides banking, insurance and port facilities for export of jute goods.

- Write four objectives of formulating National Jute Policy. In which year this policy was formulated? Do you think that the demand for jute products will pick up at global level and why?

Ans. National Jute Policy was formulated in 2005 with the following objectives:

(i) For increasing productivity of jute industry

(ii) For improving quality of jute fiber

(iii) For ensuring good prices to the jute farmers

(iv) For enhancing the yield per hectare

Yes, the demand for jute products in the world market will grow. The growing global concern for environment friendly, biodegradable material has once again opened the opportunity for jute products.

- Why are sugar mills shifting and concentrating in Southern and Western States?

Or

Why is the sugar industry rapidly shifting towards peninsular States? Give four reasons.

Ans. Sugar Industry is shifting towards Southern and Western States, because:

(i) Cane produced here has higher sucrose content.

(ii) The favourable climatic i.e., humid climate conditions ensure a longer growing and crushing season.

(iii) The co-operatives are more successful in these States and sugar industry being seasonal in nature, is ideally suited to co-operative sector.

(iv) These states have better infrastructure facilities.

- Why most of the iron and steel industries are concentrated in and around Chotanagpur Plateau Region?

Ans. Reasons:

(i) Low cost of iron ore which is mined here.

(ii) High grade raw materials is available in close proximity.

(iii) Availability of cheap labour.

(iv) Vast growth potential in the home market.

(v) Efficient transport network for their distribution to the markets and consumers

(vi) Availability of power because this region has many thermal and hydro power plants.

- “Electronic industry has revolutionsed the life of the masses and the country’s economy.” Justify the statement with five suitable arguments.

Ans. Electronic industry has revolutionized the life of the people and country’s economy because :

(i) It produce wide range of products from transistor sets to televisions and computers for the masses.

(ii) It has helped us set up telephone exchanges, telephones, cellular telecom, radios and many other equipment which have application in space technology, aviation, defence, meteorological departments.

(iii) It has generated employment for a large number of people. It employed over one million people by March 2005 out of these 30% are women employees.

(iv) This industry has been a major foreign exchange earner because of its fast growing Business Process Outsourcing (BPO) sector.

(v) India is one of the leading countries in the software development. We have 18 software technology parks which provide high data communication facility to software experts.

- How are water bodies polluted by industries?

Ans. (i) Water pollution is caused by organic and inorganic industrial wastes and affluents discharged into rivers.

(ii) Major water pollutants are dyes, detergents, acids and salts.

(iii) Heavy metals like lead and mercury pesticides, fertilizers also cause water pollution, synthetic chemicals with carbon, plastics and rubber etc. discharged in the water bodies without treatment causes pollution.

(iv) Solid wastes, e.g. fly ash, phospo-gypsum and iron and steel slags, also cause water pollution.

(v) Wastes from nuclear power plants cause pollution.

- What is manufacturing?

Ans. Manufacturing refers to conversion of raw materials into finished goods that are produced on large scale using machines.

- Name any three physical factors for the location of the industry.

Ans. Three physical factors of industrial location are:

(i) Availability of raw materials, (ii) Power, (iii) Water, (iv) Climate.

- Name any three human factors for location of an Industry.

Ans. Three human factors of industrial location are:

(i) Skilled labour (ii) Capital (iii) Market (iv) Development of transport facility.

- What are basic industries? Give an example.

Ans. Basic industries provide tools, machines and implements to manufacture other goods, e.g., Iron and steel industry.

- Name the important raw materials used in the manufacturing of cement.

Ans. Cement industry requires gypsum, limestone, silica, alumina and coal or electric power as raw materials.

- How are integrated steel plants different from mini steel plants? What problems does the industry face? What recent developments have led to a rise in the production capacity?

Ans. (i) Mini steel plants are decentralized, small, secondary units.

(ii) They have electric furnaces which produce steel using scrap and sponge iron.

(iii) They produce mild and alloy steel of various kinds.

(iv) Integrated steel plants on the other hand are large, handle everything in one complex – from transport of raw material to steel, making, rolling, shaping metal.

The problems faced by the iron and steel plants are :

(a) High costs and lack of availability of good quality coking coal.

(b) Low efficiency of labour.

(c) Erratic supply of power.

(d) Poor infrastructure facilities.

Liberalization and foreign direct investment have led to a rise in the production capacity.

- How do industries pollute the environment?

Ans. Industries cause four different kinds of pollution, namely, air, water, thermal and noise pollution.

Air pollution

(i) Is caused by the presence of undesirable gases beyond certain levels like sulphur dioxide and carbon monoxide.

(ii) the emission of smoke from chemicals paper industries, burning of fossil fuels.

(iii) leakage of poisonous gases and hazardous chemicals.

Water pollution is caused by discharge of industrial effluents into rivers. Industries like paper, chemical, textile and dyeing, tanneries, petroleum, refining, detergents, soaps that let out chemical and solid wastes pollute the water bodies.

Thermal pollution is caused by discharge of hot water from factories into rivers and ponds which affect the aquatic life. Wastes from nuclear power plants, chemicals cause land and soil pollution. Percolation of rainwater pollutes the groundwater also.

Noise pollution Undesirable noise produced from industries like pneumatic drills, construction activities cause impairment of hearing, blood pressure and other health problems.

- Discuss the steps to be taken to minimize the environmental degradation by industry.

Ans. To prevent environmental degradation caused by industries the following measures should be taken

(i) Reducing the use of water for processing by reusing and recycling at various stages.

(ii) Rainwater harvesting to meet the growing needs.

(iii) Proper treatment of hot water and effluents before discharging into rivers, etc. Industrial effluents can be treated at three stages. Primary treatment involves mechanical process like screening, grinding and sedimentation. Secondary treatment involves biological process. Tertiary treatment involves biological, chemical and physical processes.

(iv) Aerosol emissions can be reduced by the use of separators, scrubbers, filters, precipitators, etc.

(v) Selection of clean fuel and better maintenance of equipment.

(vi) Use of silencers to reduce noise pollution.

(vii) Shifting of industries away from cities.

Exercise:

- The trend of growth rate in manufacturing over the last two decades has been around _______ percent per annum,

(a) 6 (b) 7 (c) 8 (d) 9

- ____________ is not a physical factor which contributes to the location of individual industries.

(a) Power resources (b) Favorable climate (c) Labour (d) Raw materials

- On the basis of raw material used, Iron & Steel industry falls under -

(a) Heavy Industry (b) Light industry

(c) Both of the above (d) none of the above

- Most of the jute mills are concentrated in -

(a) Hugli basin (b) Damodar basin (c) Ganga basin (d) Krishna basin

- The main centre of chemical industry is

(a) Mumbai (b) Kolkatta (c) Hyderabad (d) Chennai

- Which of the following steel plants was started with the collaboration of Russia?

(a) Bhilai (b) Durgapur (c) Rourkela (d) Bhadravati

- Which of the following cities is known for silk weaving industry?

(a) Mumbai (b) Kanpur (c) Lucknow (d) Kancheepuram

- Bokaro is located in

(a) Maharashtra (b) West Bengal (c) Orissa (d) Jharkhand

- A petroleum refinery is located at

(a) Barauni (b) Kanpur (c) Barmer (d) Nagpur

- Bhilai is associated with the

(a) Cotton industry (c) iron and steel industry

(b) Silk industry (d) sugar industry

- Which one of the following industries uses limestone as a raw material?

(a) Aluminium (b)Cement (c) Sugar (d) Jute

- Which one of the following agencies markets steel for the public sector plants?

(a) HAIL (b)SAIL (c) TATA Steel (d) MNCC

- Which one of the following industries uses bauxite as a raw material?

(a) Aluminium (b)Cement (c) Jute (d) Steel

- Which one of the following industries manufactures telephones, computer, etc?

(a) Steel (b)Aluminium

(c) Electronic (d) Information Technology

- Which industry is ideally suitable for cooperative sector?

(a) Iron and steel (b)Cotton textile

(c) Sugar Industry (d) Electronic Industry

- To improve the efficiency of manufacturing industry government has established

(a) NMCC (b)ICAR

(c) GAIL (d) None of the above

- At which place there is no software technology park

(a) Guwahati (b)Mohali (c) Noida (d) Lucknow

- Which industry is concentrated in west Bengal?

(a) Cotton textile (b)Aluminium (c) Jute textile (d) Woolen textile

- Which is called golden fiber?

(a) Cotton (b)Silk (c) Jute (d) Nylon

- Which component of fertilizer is entirely?

(a) Nitrogen (b) Phosphate (c) Lime (d) Potash

ANSWERS TO EXERCISE – 1

- (b)

- (c)

- (a)

- (a)

- (a)

- (a)

- (d)

- (d)

- (a)

- (c)

- (b)

- (b)

- (a)

- (c)

- (c)

- (a)

- (d)

- (c)

- (c)

- (d)

EXERCISE – 2

- What is the objective of setting up National Manufacturing Competitiveness Council?

- What do you understand by agglomeration economies?

- Why our garment manufacturers have to import fabric although our spinning mills are competitive at the global level?

- What are the challenges faced by the jute industries in India?

- Distinguish between agro based and mineral based industries.

- Why is iron and steel industry called as the heavy industry?

- What are the two types of chemical industries? How are they useful?

- Name the important raw materials used in the manufacturing of cement?

- Under which sector do BHEL and SAIL come?

- Which country is the largest producer of raw jute and jute goods?

- Which industrv use bauxite as a raw material?

- Which industry is best suited for co-operative sector?

- What is the significance of industries?

- How would you classify industries on the basis of the number of labor employed, on the basis of ownership?

- Why are the jute textile mills concentrated along the Hughli river?

- What is the importance of fertilizer industry? Explain the development of fertilizer industry in India.

- Distinguish between heavy and light industries with one example of each.

- Why most of the cotton textile industries are located in Maharashtra and Gujarat?

- In which sector does the Jamshedpur steel plant fall with reference to ownership? Why is it located at Jamshedpur?

- What are Agro-based industries? Why is the sugar industry shifting southwards?

- Write a short note on the electronic industry.

- What is the importance of Sugar industry? Explain the development of Indian sugar industry.

- Write a short note on the cement industry.

- The Jute industry in India has been passing through difficult times. Explain.

- Give reason why the Iron and Steel industry are concentrated in certain pockets only.

- Why are the cotton textile mills spread all over India? Explain three reasons with suitable examples.

- How does industrial pollution degrade environment?

- Suggest measures to control the degradation of the environment.

- What is the significance of the Iron and Steel Industry?

- Give an account of the sugar industry in India.

- Why is the Iron and Steel Industry called a heavy and basic industry? Give two reasons for each.

- Why have most of the iron and steel plant been set up in the public sector? Explain four reasons.

- Name the oil refineries located in Haryana and Bihar states.

- Name the Nuclear power plants located in Uttar Pradesh and Karnataka states.

- Name the iron and Steel plants located in Chattisgarh and Orissa states.

- Name the software technology parks located in Jammu and Kashmir and Kerala states.

- Why is the iron and steel industry mainly located in northeastern parts of the Indian Peninsula?

- What are the problems being faced by the Indian cotton industry? Suggest three ways to solve them.